If you’ve been following my urban exploration adventures last year. In that case, you will know that in my adventures, I much prefer industrial abandonments, the big, empty, massive factories. At one point, North American Rayon was a sprawling industrial complex that dates back to the early 20th century. Today, only a single building is left, tucked away on the banks of the Watauga River. Thankfully, I checked out the original power station and the ruins of a surviving section before their demolition, the surviving building I checked out a couple of times. The part I never had the chance to check out was the sister plant, Bemberg, mainly due to time and dogs.

Nikon D300 – AF-S Nikkor 14-24mm 1:2.8G

The history of North American Rayon is messy, it twists and turns and is certainly not a straight line, especially when you’re dealing with multiple businesses in Europe, mergers, the Third Reich and World War Two. What would become North American Rayon starts in Prussia, Johann Peter Bemberg had taken over the family wine trading business after the death of his brother in 1790, JP Bemberg decided to put his name on the business and transition to the trade of dye and cloth. The business would pass to Bemberg’s son in 1843 and then his son-in-law in 1847, but the Bemberg name stuck as did the product. The invention of artificial silk would catch the company’s eye and in 1897 a factory opened to produce rayon using the cuprammonium process. While this process produced a high-quality rayon, it was not the only method. In 1899, Vereinigte Glanzstoff-Fabriken (VGF) would begin producing rayon using the viscose process. Bemberg went public in 1903 (JP Bemberg AG), and in 1911 VGF began to purchase shares in Bemberg. The two firms entered a technology sharing agreement in 1916 and by 1925 VGF had full control over Bemberg and another German company, IG Farben also purchased a share in VGF. Seeking to expand the market, American Bemberg incorporated that same year. Attracted to the water supply, mineral availability, and a docile workforce (non-union) in the southern United States, construction started on a Bemberg factory in Elizabethton, Tennessee. Construction lasted under a year and in 1926 production of rayon using the cuprammonium process started. The early years of American Bemberg was marked by several small labour disputes and saw the formation of Local 1630 of the United Textile Workers union. In 1928, VGF opened a second plant to produce rayon using the viscose process incorporated under the name American Glanzstoff. In 1929 the two largest rayon producers in Europe, Enka and VGF merged into a holding company, Algemene Kunstzijde Unie (AKU), which included both VGF’s and Enka’s North American corporations. Despite the great depression, the plants in Elizabethton continued to operate as the demand for rayon continued to grow in the North American market and was able to maintain a stable economy in the region. By the 1930s, the two plants became collectively known as North American Rayon, although continued to operate semi-autonomously. With a combined workforce of 4,500, they were the single largest employer in Elizabethton. In Germany, the Third Reich had started to nationalise key industries as part of their efforts to prepare of war, while they were asked about nationlising VGF, they sidestepped the issue to make it appear that the company was owned by the Dutch, to protect the American holdings. But that didn’t stop the government from interfering in operations. When the United States did enter the war on the side of the allies, demand for rayon increased. And because of the partial ownership the Office of Alien Property began an investigation of North American Rayon in 1942. Because of the complex nature and thanks to efforts in the previous decade, the OAP did not seize the company. It did mean that the profits did get funneled back to AKU in Europe which was at least partially owned by an enemy state. In the post-war era, North American Rayon was turned over to the American government and AKU waved all ownership in 1947, but was able to retain ownership of Enka. In 1948, both Elizabethton plants were sold to Beaunit Mills who were looking into starting up a rayon production line.

Nikon D300 – AF-S Nikkor 14-24mm 1:2.8G

Nikon D300 – AF-S Nikkor 14-24mm 1:2.8G

Nikon D300 – AF-S Nikkor 14-24mm 1:2.8G

Nikon D300 – AF-S Nikkor 14-24mm 1:2.8G

Nikon D300 – AF-S Nikkor 14-24mm 1:2.8G

By the 1950s the demand for different artifical fabrics outstripped the demand for rayon, Beaunit converted the Bemberg plant to produce polyester while the American Glanzstoff would produce nylon. The mid-century also brought a great deal of labour unrest and the collapse of low-wage industries in the American south. El Paso Natural Gas took control of Beaunit Mills in 1961 and began to produce a new style of nylon in Elizabethton, but by this point the demand for artificial fabric dropped. Labour troubles continued at both plants through the 1960s, El Paso pointed the finger at the drop in demand, while the unions blamed mis-management by El Paso. Whatever the exact cause is, by 1967 the workforce at North American Rayon dropped by 50% by the end of the decade from the wartime peak. A damning report by the Environmental Protection Agency pointed to the Bemberg plant as a major polluter, the years of using the cuprammonium process resulted in a great deal of pollution in the Watauga River. With no money to build a water treatment plant, El Paso shuttered the Bemberg plant and spun it off into a holding company. Work continued in the North American Rayon plant. Through the 1970s both plants would be shuffled around through various holding companies, before both ended up in the hands of Jim Walker by 1977. Bemberg never produced rayon again, but at North American Rayon the works continued producing rayon for furniture, apparel, and industrial purposes. A water treatment plant would be finally completed in 1980 to help clean up the toxic pollution. Walker would present his workforce with offer to become employee-owners of North American Rayon, the workers originally rejected the deal, but under instructions from the Union accepted and it resulted in an increase in wages. MKS Polyester purchased North American Rayon in 1988, converting the plant to produce carbonised rayon for use as engine lining for the solid rocket boosters used in the Space Shuttle program. Increased competition from outside North America put a great deal of strain on American producers, this turned the 1990s into a decade of labour disputes and layoffs. These started off small, but culminated in the loss of 1,300 jobs in 1997 leaving only a few hundred employees at North American Rayon. On Friday 25 February 2000 disaster hit, at 4:30 am a small fire broke out in the shipping & receiving area, the half-dozen employees still in the building were alerted when the sprinklers activated. After trying to knock down the fire with extinguishers it had spread quickly fueled by the piles of cardboard. By the time the fire department arrived then entire plant had been engulphed. Between the chemicals and the tarred roof the building burned so hot that the fire department, who had a limited water supply, could only prevent the fire from spreading to nearby buildings. It took a week to put the fire out, and most of the plant was demolished. By 2012 only the water treatment plant, power station, and the shell of Unit 3 remained, but two years later Unit 3 and the power station had been knocked down. In an odd twist, the Bemberg plant is still standing as of 2024, but is occupied by another business who even have stationed guard dogs.

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Adox CHS 100 ART @ ASA-100 – Processing By: Old School Photo Lab

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Adox CHS 100 ART @ ASA-100 – Processing By: Old School Photo Lab

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Adox CHS 100 ART @ ASA-100 – Processing By: Old School Photo Lab

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Adox CHS 100 ART @ ASA-100 – Processing By: Old School Photo Lab

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Adox CHS 100 ART @ ASA-100 – Processing By: Old School Photo Lab

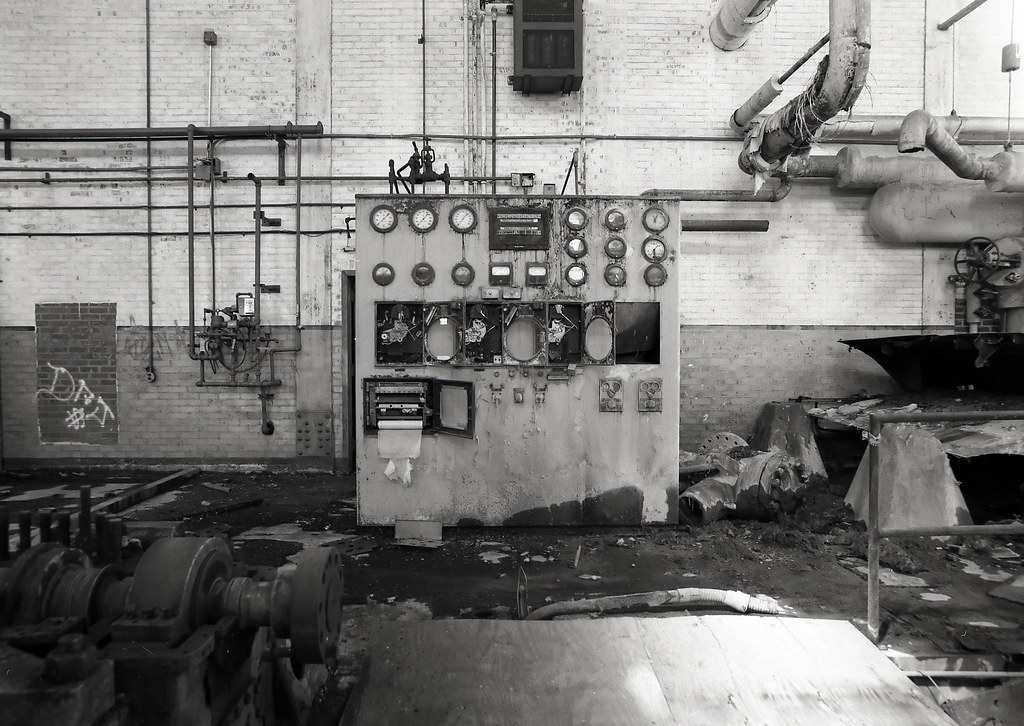

I had run into DJ Craig outside the Dayton Executive Hotel during the first VCXPEX event, and he mentioned that he planned to revive the Mid-Atlantic Meetup in the spring and asked if I would want to join. What turned out to be MAMU IV still ranks among my favourite Urban Exploration Events. It had everything: epic locations, a good group of explorers, an epic rescue, and parties late into the night. So, in early April 2012, I drove from Milton to Tennessee for twelve hours (but longer with stops). While the drive prevented me from joining the sleepover at Government Spiders, I had a fantastic drive. I fell for the long solo road trip. On the third day, we all headed out to Elizabethton, Tennessee, to check out the remains of North American Rayon. At the time, I did not know this was North American Rayon; some of the group went to check out Bemberg while others went to Old King Coal. Remember, we tended to use code names for locations to keep things out of the public eye, especially in small towns where these places were well known. It’s easy to hide in plain sight. When the smaller businesses around our path into the power station were closed for the weekend. Everyone else was more concerned with making their Walmart run; we quickly slipped in without trouble. Well, I ended up catching my pants on a fence and tore out the crotch. I wasn’t about to turn around and find new pants; a quick patch job with duct tape, and we were inside. The power station started small and cramped, and I was concerned it wouldn’t be that interesting. Then we got into the main generator hall, and things got interesting. Old King Coal was smaller than others, as power stations go, but it was only to run a factory, not a growing city. There was a tonne of equipment left over when the plant burned. The power station was spared from the fire and eventual demolition twelve years prior. However, they left everything and walked away. Some vandalism, documents, spare parts, controls, but nothing too serious. After I had my fill, I wandered the other side of the station and walked into the Walmart to get a new pair of pants. No one blinked an eye at a guy with a camera pack stepping through a hole in the fence. The Walmart itself was an experience; if you remember the old website, People of Walmart, yeah, that’s precisely what it was. After getting the pants, I headed back out; the ruins of Unit 3 were nearby and wide open, so I wandered around there for a bit. Some standing buildings were still left, but I had been warned against going inside. Unit 3 was attractive as it was an industrial ruin; you could see where the fire had ripped through the building. But what struck me was the presence of cars; some looked pretty new and had recent tags. Had I run across a chop shop? I wasn’t about to stick around and left quickly after issuing First Aid to another explorer who knocked their head at Old King Coal. The original plan had been to hit up Bemberg, which looked amazing from the exterior. Still, the first group had encountered dogs, not only dogs on the ground but security dogs on the roof. Don’t get me wrong, I like dogs; I don’t like guard dogs in the United States. It wasn’t until 2014 that I reached the water treatment plant, another easy access spot well behind many busy commercial centres. It also proved to be the cherry on top of my rather epic personal MAMU journey, starting in Louisville, Knoxville, Nashville, and then back to Johnson City and the surrounding area. It also was the first time I heard the name North American Rayon; the water treatment plant proved small but interesting, with a lot left over and some interesting scenes to photograph. What was more interesting was that someone decided to paint a lovely mural across the river-side wall of the treatment plant. I would return for a daring daylight weekday attempt at the treatment plant. I thought the entire building was abandoned, and I was at least partly right. I had shot some digitals, a roll of 120 and half a roll of Kodak Technical Pan. Things were going well; I got in without incident, was wandering around, and then I heard voices coming from another section of the plant, an active section. I looked down from a window into what looked like a mechanic shop. I left quickly and drove to Johnston City to finish that roll of Technical Pan.

Nikon F3 – Nikon Series E 28mm 1:2.8 – Eastman-Kodak Double-X 5222 @ ASA-250 – Processing By: Old School Photo Lab

Nikon F3 – Nikon Series E 28mm 1:2.8 – Eastman-Kodak Double-X 5222 @ ASA-250 – Processing By: Old School Photo Lab

Nikon F3 – Nikon Series E 28mm 1:2.8 – Eastman-Kodak Double-X 5222 @ ASA-250 – Processing By: Old School Photo Lab

Nikon F3 – Nikon Series E 28mm 1:2.8 – Eastman-Kodak Double-X 5222 @ ASA-250 – Processing By: Old School Photo Lab

Nikon F3 – Nikon Series E 28mm 1:2.8 – Eastman-Kodak Double-X 5222 @ ASA-250 – Processing By: Old School Photo Lab

I like my photos I got here, they show my attention to detail and composition and exploration of black & white film. Clean leading lines are a hallmark of my later photography in urban exploration. Since all the trips were pretty close together there wasn’t much growth between them. I do like my use of ultra-wide angle lenses in all cases. The one thing I am not too happy about is my images from Unit 3, I didn’t get a single digital image. I should also note I think this is one of the first times I used Eastman Double-X a classic cinefilm that I had picked up several rolls and got processed through Old School Photo Lab which used HC-110 for processing. Not my favourite developer with the film especially at t he stronger dilutions.

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Kodak Portra 400 @ ASA-800 – Processed By: Burlington Camera

Sony a6000 – Sony E PZ 16-50mm 1:3.5-5.6 OSS

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Kodak Portra 400 @ ASA-800 – Processed By: Burlington Camera

Sony a6000 – Sony E PZ 16-50mm 1:3.5-5.6 OSS

Pentax 645 – SMC Pentax A 645 35mm 1:3.5 – Kodak Portra 400 @ ASA-800 – Processed By: Burlington Camera

I’m not one to relish the idea that a good spot to explore comes from a local tragedy. Like Detroit’s vast inventory of abandoned buildings, the loss of North American Rayon proved to be a significant hit to the area. But even before the entire place burned, the damage had already been done through years of attrition and job loss. Despite this, the city today remains reasonably well off, with a good population size and socio-economic standing for the area. The one thing that I do wish that I could have seen is the relatively intact Bemberg plant. The place seemed active even on my one return visit to the treatment plant, and I could see the dogs roaming inside the fence. And that whole risk-to-reward calculation put the risk far too high for the potential yet unknown rewards. I even flipped through publicly available photos on Flickr. I only saw external shots of Bemberg (but I did see some from a Bemberg plant in Italy). While I had originally had the three surviving locations divided into sperate albums, since writing this piece I have combined all the images into a single album, you can check it out over on Flickr.

Nikon F5 – AF-S Nikkor 14-24mm 1:2.8G – Kodak Technical Pan @ ASA-25 – PMK Pyro (1+2+100) 11:30 @ 20C

Nikon F5 – AF-S Nikkor 14-24mm 1:2.8G – Kodak Technical Pan @ ASA-25 – PMK Pyro (1+2+100) 11:30 @ 20C

Nikon F5 – AF-S Nikkor 14-24mm 1:2.8G – Kodak Technical Pan @ ASA-25 – PMK Pyro (1+2+100) 11:30 @ 20C

Nikon F5 – AF-S Nikkor 14-24mm 1:2.8G – Kodak Technical Pan @ ASA-25 – PMK Pyro (1+2+100) 11:30 @ 20C

Nikon F5 – AF-S Nikkor 14-24mm 1:2.8G – Kodak Technical Pan @ ASA-25 – PMK Pyro (1+2+100) 11:30 @ 20C

Glossary of Terms

Cuprammonium: Also known as Schweizer’s reagent is the metal ammine complex with the formula [Cu(NH3)4(H2O)2](OH)2. This deep-blue compound is used in purifying cellulose. It is prepared by dissolving copper(II) hydroxide in a solution of ammonia. Schweizer’s reagent was once used in production of cellulose products such as rayon and cellophane. Cellulose, which is quite insoluble in water (hence its utility as clothing), dissolves in the presence of Schweizer’s reagent. Using the reagent, cellulose can be extracted from wood pulp, cotton fiber, and other natural cellulose sources. Cellulose precipitates when the solution is acidified. It functions by binding to vicinal diols.

Viscose: English chemist Charles Frederick Cross and his collaborators, Edward John Bevan and Clayton Beadle, patented their artificial silk in 1894. They named it “viscose” because its production involved the intermediacy of a highly viscous solution.

Office of Alien Property: The Office of Alien Property was an office within the government of the United States during World War I and again during World War II, serving as a custodian to property that belonged to US enemies. The office was created in 1917 under the Trading with the Enemy Act of 1917 (TWEA) in order to assume control and dispose of enemy-owned property in the United States and its possessions.

I used to work at NAR in Tennessee . Work almost all the jobs in power plant up to switch board operator